Maximize ROI by Overcoming These Common Challenges

Balancing cost, quality, and lead time is a challenge that many businesses face when working with machined parts manufacturers. These three factors are often intertwined, making it difficult to prioritize one without impacting the others. In this blog, we’re exploring how to tackle these challenges head-on, offering practical tips to help you optimize your processes and build stronger relationships with your suppliers.

Cost Challenges

There are a few cost challenges that can cause prices to rise for machined parts manufacturers and their clients. Fluctuating material prices can make it difficult to control expenses. Additionally, there’s been a shortage of skilled workers within the United States, which can drive costs up.

Overall, it can be difficult to balance cost-cutting measures without compromising quality. But, there are a few things you can do. Choosing cost-effective materials and creating strategic sourcing and supplier relationships can help you achieve better pricing and stability. Additionally, working with machined parts manufacturers that prioritize lean manufacturing can help you streamline operations and maximize ROI.

Quality Challenges

Maintaining high precision and tight tolerances across long production runs can be difficult. This increases the risk of defects or variations in the manufacturing process. Working with a manufacturer that’s experienced in your area can help you avoid these issues. Additionally, looking for certifications like ISO 9001:2015 can give you confidence that your machined part manufacturer will create high-quality products.

Lead Time Challenges

Lead time challenges occur all too often in the manufacturing space. Delays can be due to supply chain issues, including raw materials and tooling. Machinery downtime and breakdowns on production schedules can also cause major issues in your go-to-market strategy. That’s why it’s so important to work with experienced machined parts manufacturers like KAL Manufacturing.

At KAL Manufacturing, we work with an established, successful supply chain that mitigates any issues you may face with sourcing materials. Additionally, we assign a program manager to your project to be the single point of contact for the duration of the program lifecycle. This ensures efficient turnaround, seamless integration, continuous documentation, and real-time status updates. We can also offer engineering support to streamline your part design from a manufacturability standpoint, which can speed up the production process. All of these combined points allow us to help you get to market faster.

Work with KAL Manufacturing for Your Machined Parts

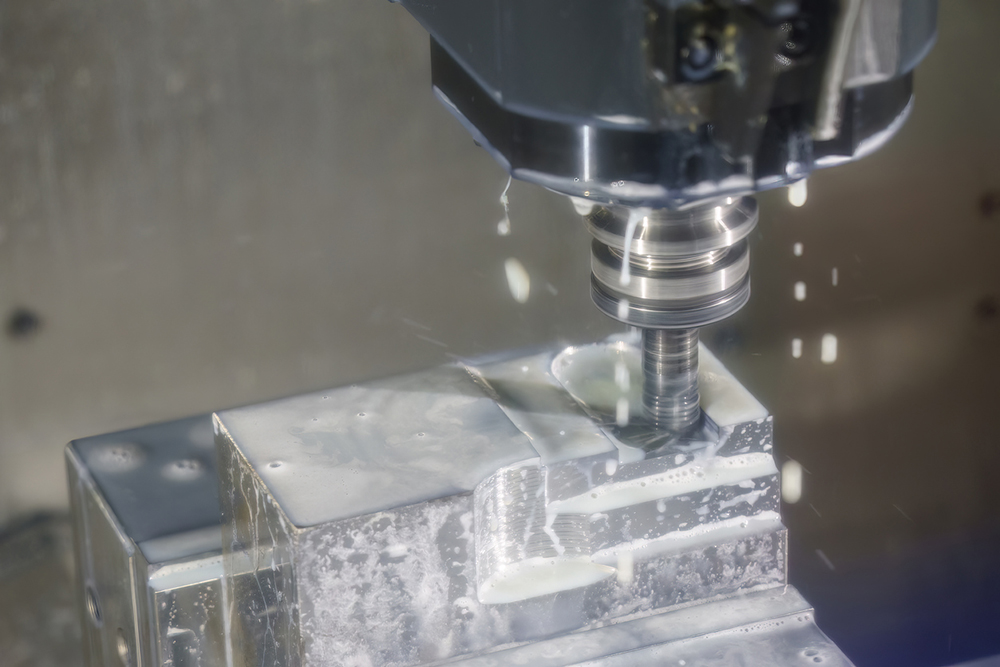

If you’re looking for reliable machined parts manufacturers, turn to KAL Manufacturing. Since 1943, we’ve been dedicated to crafting high-quality custom-machined parts. We have a variety of extensive capabilities, such as CNC machining, sheet metal fabrication, electro-mechanical assembly, and prototyping. We have experience helping OEMs and Fortune 500 companies create machined parts that exceed expectations, and we’re ready to help you with your next project.

Our shop has advanced machinery that can achieve tolerances down to 0.003-0.005 inches. We’re equipped with 20,000 RPM dual pallet, high-speed machining centers with fourth-axis capabilities and vertical machining centers. Additionally, we have a complete line of tool room support equipment. This extensive machinery allows us to build tooling in-house and take on projects of all volumes and material types. Whether your part must be made of aluminum, steel, stainless steel, or plastic, we can help.

Let’s Get Started

Want to learn more about what we can do for you? Contact our expert team today to get started.