At KAL Manufacturing, we maintain a variety of equipment to offer robust capabilities for our clients. This machinery allows us to manufacture the highest quality parts for your next project, allowing you to get your products to market as quickly as possible.

The following is an overview of our offerings. Please contact us here if you have any questions or are interested in learning more about how KAL Manufacturing can help with your next project.

MANUFACTURING FACILITY

- 40,000 square feet of manufacturing space

- 10,000 square foot distribution center

CERTIFICATIONS

- ISO 9001:2015

- ITAR registered

- ORCA registered

- CCR registered

SUPPORTING SOFTWARE

- Epicor 10 – ERP

- SolidWorks – design

- Mastercam – machining

- FabriWin – sheet metal inspection

- PCDMIS – quality assurance

- QC-CALC – CPK analysis & histograms

- eDrawings – CAD file viewer

FABRICATING DEPARTMENT

- (1) Amada LC2515 C1 AJ Combination Fiber Laser/Turret with Amada ASR 3015 NTR Auto Load/Unload

CNC PRESS BRAKES

- (1) 240 ton Amada Procam 14’ bed with 6-axis backgauge

- (2) 80 ton Amada with N/C and FineAlpha Bender – 9EX backgauge

- (2) 50 ton Amada with N/C and FineAlpha Bender – 9EX backgauge

WELDING EQUIPMENT

- (1) Amada America ID40ST spot welder

- (3) Miller Dynasty 350 tig welder

- (1) Miller Dynasty 280 tig welder

- (1) PAK 50 plasma torch

- (2) Diversitech downdraft table

PUNCH PRESSES

- (1) 110-ton Stamtec

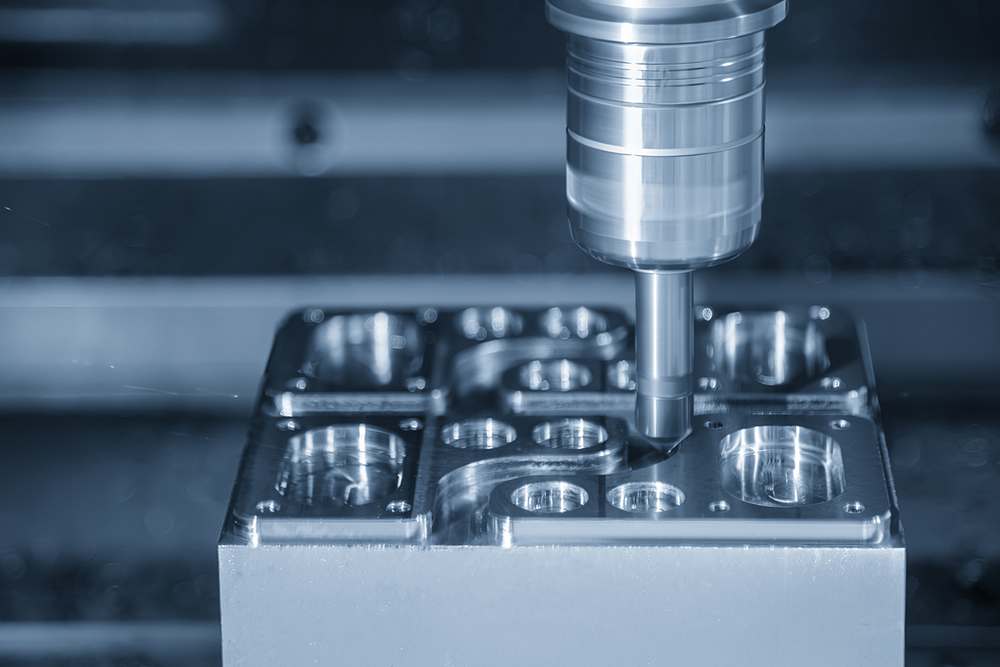

MACHINING DEPARTMENT

- (2) DMG Mori NHX 4000 2nd Gen horizontal machining centers

- (1) KIWA KH 4100 duel pallet horizontal machining center

- (3) Fanuc T-21-iFLa Robo Drill with pallet changer

- (1) DMG Mori Eco Mill 1100 vertical machining center

- (1) Fanuc (1X) A-T21-iEL robo drill with pallet dual changer

- (1) Fanuc (1X) E-T14-iBL robo drill with pallet dual changer

- (1) Proto Trak SMX

SURFACE FINISHING

- (1)-Steelmaster SMW-533 Profiline deburring/grinding

- (1) Lissmac SMW-123- deburring/surface finishing

- (1) P & G sandblaster

- (1) Rosemont tumbler

- (1) Raytech 75 tumbler

LATHES

- (1) Kia Turn 15 turning center — 15” between centers

HARDWARE INSERTION

- (4) Haeger Automatic Pemserters

- (6) Pneumatic STI insertion tools

- (2) Pneumatic rivnut setters

- (3) Pneumatic rivet guns

ASSEMBLY DEPARTMENT

- (10) Flexible work stations

- (1) Electrical and PCB testing

- (1) ESDS controlled

- (5) Magnification/inspection centers

- (1) Serialization and barcoding

TOOL ROOM DEPARTMENT

- (5) Bridgeport milling machines w/N.C. controllers

QA EQUIPMENT

- (1) Brown & Sharp Global — automatic CMM with Tesa Star Head

- (1) Fabri Vision 4X4 — digitizing part scanner

- (1) Starrett horizontal digital video measurement system HDV400

- (1) Tesa hite 700 — digital height stand with SPC output

- (1) Tesa hite 400 — digital height stand with SPC output

- (5) Mitutoyo — 24” twin beam height stands

- (1) Mitutoyo — Profilometer

- (4) Starret — internal bore micrometers

- (1) Deltronic gauges

- (1) Imada ESH push/pull force gage 0-500 lbs

- (1) Imada FB push/pull force gage 0-100 lbs

Ready to take the next step?

KAL Manufacturing would love to hear how we can help with your next project. Please contact us here with any questions you may have.

Additionally, you can download the above equipment and capabilities list in PDF form here.